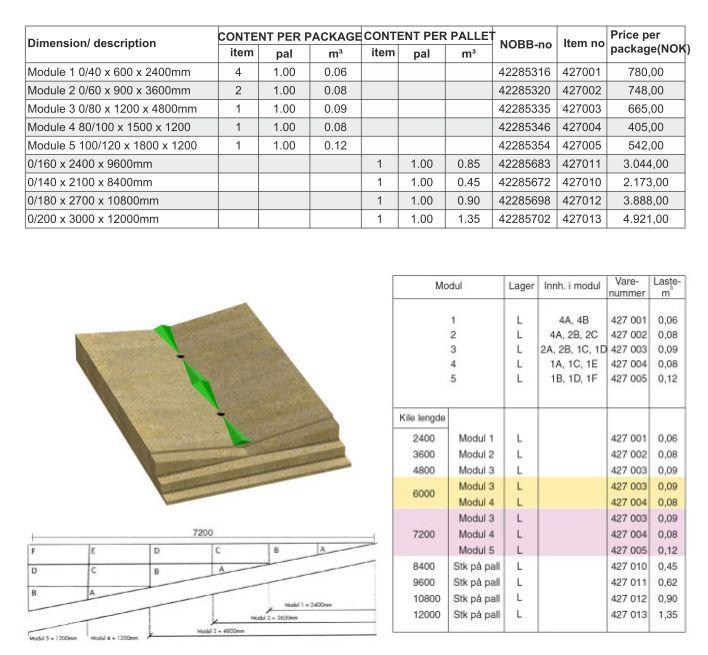

Advantages of the Fast Roof technology

Easy-to-calculate savings

We provide high expense and financial saving opportunities connected with the thermal insulation layer thanks to:

-

the optimization of thermal insulation and roof drainage design respecting the guidelines of the architectural and construction design, as well as

-

“module arrangement” methodology during the installation of thermal insulation panels and rolled waterproofing panels – directly on the roof.

thanks to precise prefabricated performance and the marking of panels according to the “module arrangement” methodology;

in Scandinavian countries, our roofs are usually assembled by two apt roofers irrespective of roof size thanks to:

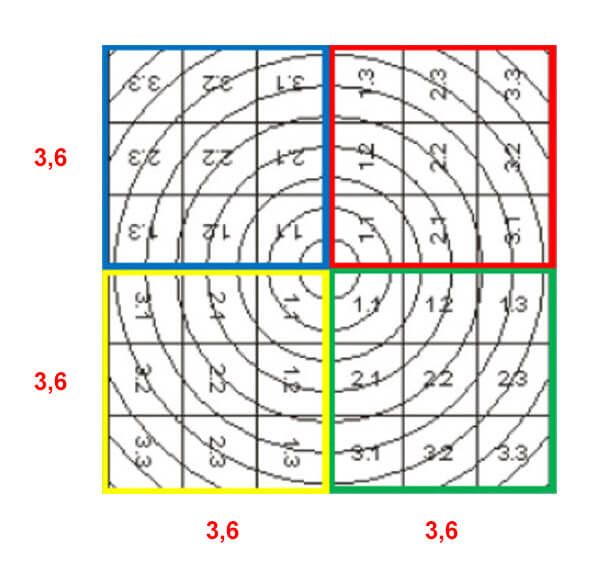

- easy application of thermal insulation panels according to the simple “module arrangement” design – it is not necessary to form pitches on the roof – you simply arrange thermal insulation “modules” and there is no place where you could make a mistake;

- simple and quick application of the fixing/welding of roof felts or synthetic membranes as our pitches head straight towards roof drains and are unnoticeable while unfolding rolled waterproofing;

even several times – on the efficiency and speed of roofing works

up to 30% on the costs of hiring roofers

- easy application of thermal insulation panels according to the simple “puzzle arrangement” design – it is not necessary to form pitches on the roof – you simply arrange thermal insulation “puzzles” and there is no place where you could make a mistake;

- simple and quick application of the fixing/welding of roof felts or synthetic membranes as our pitches head straight towards roof drains and are unnoticeable while unfolding rolled waterproofing;

up to even 30% – on the number of thermal insulation panels applied

up to even 30% – on the number of applied rolled waterproofing materials (roof felt, PVC, TPO etc.)

up to even 25% – on the quantity of thermal insulation material waste

longer exploitation of the roof without previous intervention and exploitation risk of damaging waterproofing cover

Comparison of CIRCULATE PITCHES vs. traditional ones: the roof of 51,84 m²

One of large Scandinavian companies manufacturing thermal insulation roof panels conducted an interesting independent comparative experiment of the same “roof” in 3 different technologies of pitch panels commonly applied on the Scandinavian market.

FastRoof team was invited to take part in the experiment as one of completely neutral observers. FastRoof team did not take an active part in the project. The recording and summary under the form of a chart presenting the comparison of experiment results was prepared by an objective Organizer’s Team.

The experiment consisted in comparing for exactly the same roof the installation of 3 different technologies for the application of thermal insulation pitch panels and rolled roof felt waterproofing performed by the same professional roofers/experts possessing extensive experience and familiar with the technology thanks to their everyday work on Scandinavian roofs.

FAST ROOF CIRCULATE roof

| Activity | Time |

|---|---|

Planning | — |

Thermal panel | 7 min |

Roof felt | 4 min 30 s |

TOGETHER | 11 min 30 s |

Waste: thermal panel | — |

Waste: roof felt | — |

Welding | — |

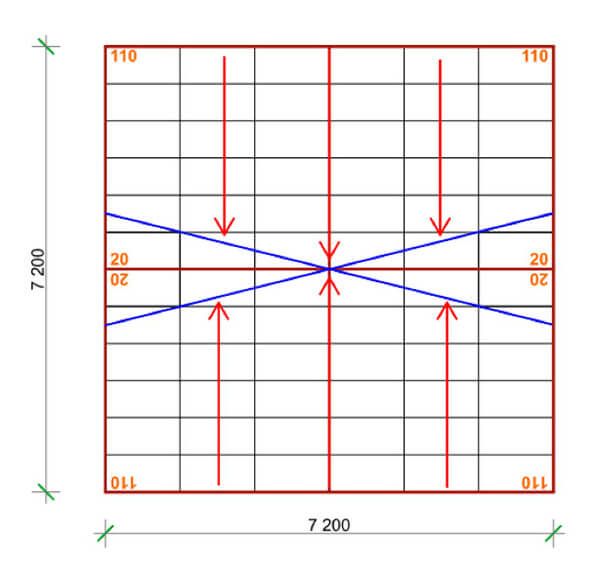

TRADITIONAL 2-WAY roof

| Activity | Time |

|---|---|

Planning | 3 min 45 s |

Thermal panel | 21 min 15 s |

Roof felt | 12 min 45 s |

TOGETHER | 37 min 45 s |

Waste: thermal panel | — |

Waste: roof felt | 18 m² |

Welding | 2.5x longer |

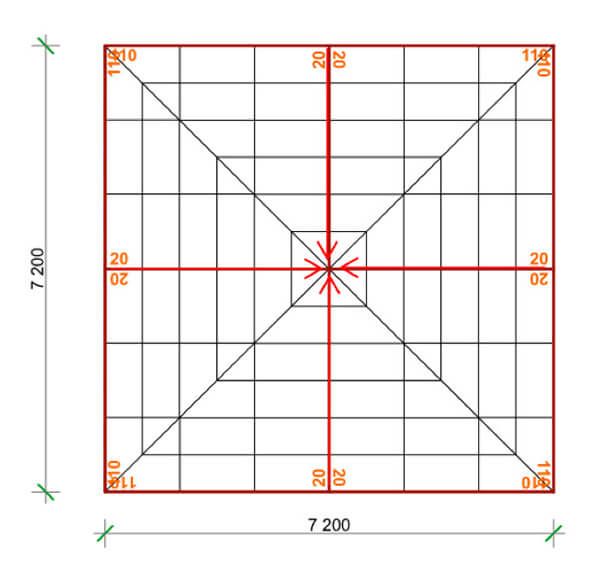

TRADITIONAL 4-WAY roof

| Activity | Time |

|---|---|

Planning | 3 min 45 s |

Thermal panel | 43 min |

Roof felt | 18 min |

TOGETHER | 1 hour 4 min 25 s |

Waste: thermal panel | 30 m² |

Waste: roof felt | 25 m² |

Welding | 3x longer |